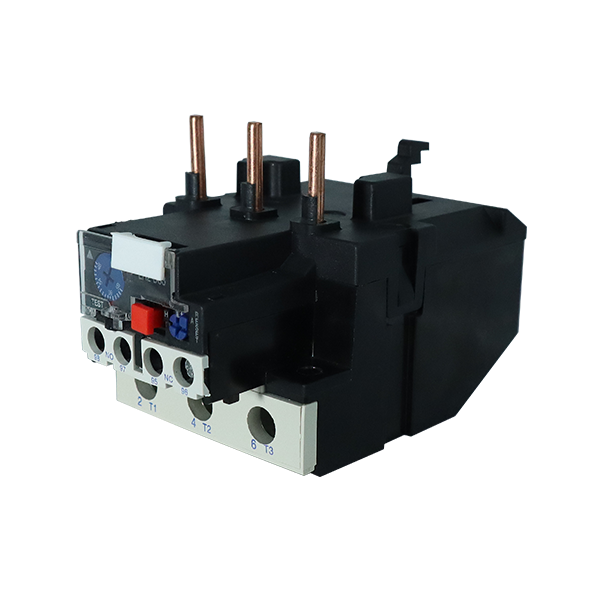

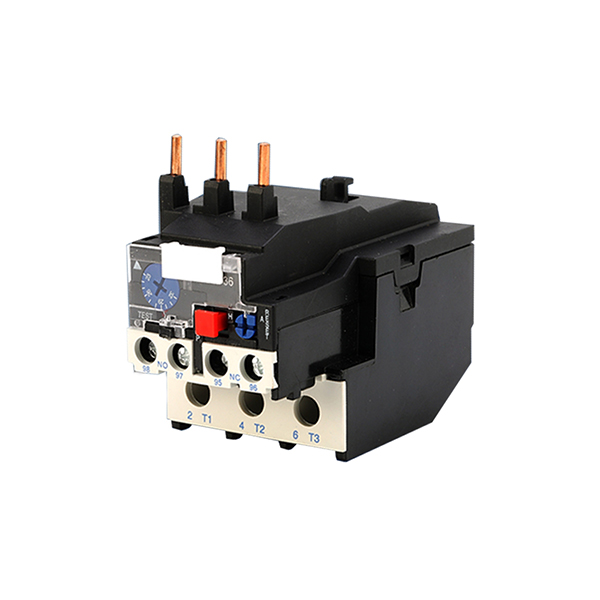

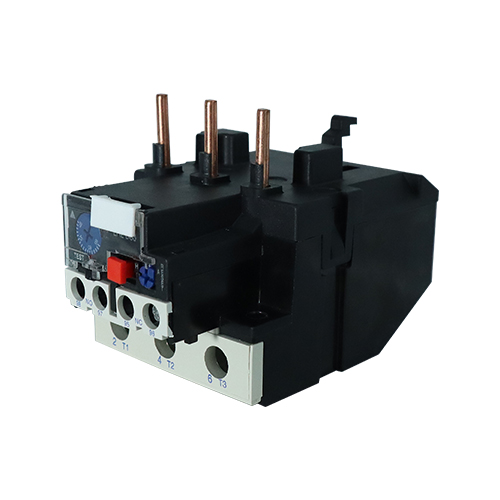

Thermal Overload Relays

Thermal overload relay is used for overload protection of motor or other electrical equipment and electrical lines. As a type of overload protection component, thermal relay has wide applications in production due to its small size, simple structure, and low price.

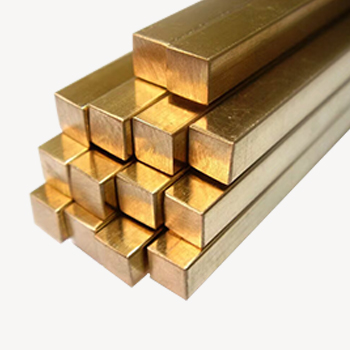

ATO supplier in China manufactures JR28 and JR36 two series 3 phase thermal overload relays. 25A, 32A, 36A, 63A, 93A, 160A rated current can be chosen. The 3-phase thermal overload relay is equipped with a flame retardant shell to withstand wear and high temperature. Three-phase thermal relay is often used in AC motors.