ATO Relays DIN Rail Mounting

What is DIN Rail

DIN rail is an installation method for electrical components in German industrial standards, and it has been widely used in field installation environments such as electric power and industrial automation. From the PLC installation in the control cabinet of the control room to various control electrical devices such as surge protectors, safety barriers, terminal blocks, etc., they are all installed on DIN rails to make them fixed. It has become a standard mounting rail for mechanical supports of various industrial electrical devices. Since it is only necessary to drill holes on the DIN rail and fix it on the backplane in the control cabinet or field junction box with a small number of screws, and then clip various electrical devices to the rail through the rail clips on the device, the installation is more convenient. And the device can be installed closely, so DIN rail has always been favored by ATO and other electrical device manufacturers in the field of industrial automation.

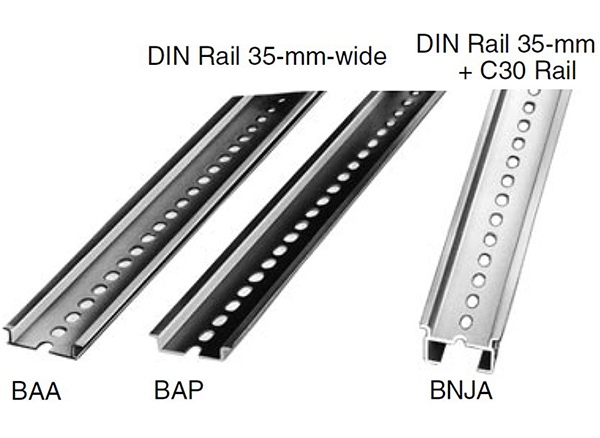

Dimensions of DIN Rail

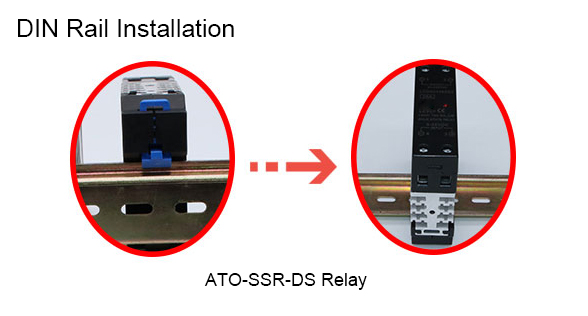

The size of DIN rail is usually marked with "width * depth * thickness". At present, the most commonly used width size is 35mm, thickness size is 1mm, and the depth is formulated according to the on-site installation requirements. Common DIN rail sizes are: 35*7.5*1, 35*15*1, 35*15*1.5, 32*15*1.5, 35*16*1.8, etc. Since ATO-SSR-DS series solid state relay mounts on the standard 35mm DIN rail installation with other DIN rail mounted components is quick and easy. Now, for the field of industrial automation, DIN rail is commonly used for on-site installation equipment, such as PLC (programmable logic controller), contactor, relay, terminal block, surge protector, circuit breaker, etc.

Advantages of DIN Rail Mounting

- The most important advantage is that it saves time and effort so that components can be simply fixed or slid onto the rails without requiring the user to install each component individually on the panel.

- The rail saves space, because the DIN rail allows the close arrangement of components, providing a convenient place to ideally combine internal and external wiring circuits in a limited space.

- From the price of DIN rail itself and the potential for high-density installation, they are cost-effective and can reduce the total amount of wires and the required internal space.

- DIN rail adheres to general dimensions and installation protocols, supports a series of general standard widths and shapes of installation hardware, and related products can ensure the consistency of dimensions.

- The DIN rail system allows builders the flexibility to mix and match components without having to stick to a single proprietary model to get the job done.

DIN Rail Mounting Disadvantages

Although the DIN rail installation of industrial automation field electrical devices has many advantages such as full utilization of space and convenient installation, it also has shortcomings. Due to the complexity of the industrial automation field control system, there are many control system equipment involved, and the control cabinet or the current control junction box has limited space, which will inevitably lead to high equipment density and limited maintenance and repair space. If it involves damage to some electrical components, need to be replaced. Usually, this type of electrical device is mechanically fixed to the DIN rail by means of a buckle. The disassembly requires a certain amount of force, and the space is limited, which often leads to maintenance and repair personnel being unable to directly disassemble the electrical device that needs to be replaced.

How to Improve the Disadvantages?

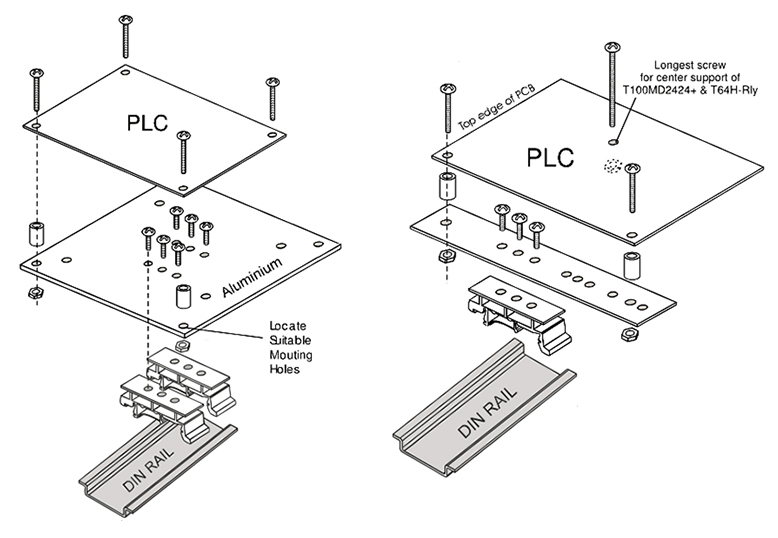

In order to solve the problems caused by the above-mentioned DIN rail installation, ATO Relay Manufacturer proposes an improved method to avoid the emergence of new problems. The solution is to add an electrical device holder in the middle. The function of the electrical device holder is to mechanically connect to the DIN rail through the DIN rail buckle of the holder itself, and the electrical components are installed on the holder instead of the DIN rail. The electrical device is fixed on the electrical device card holder in the form of a card key (like the memory in the desktop computer host is installed in the memory card slot). Since the connection part of the three has a metal conductor connection, it is protected from electrical grounding. From the perspective of the electrical device, the electrical device holder and the electrical device are a whole, so it is only necessary to do unified electrical grounding protection on the guide rail and connect it to the grounding busbar, and the grounding connection resistance is less than 1Ω and the grounding resistance is less than 4Ω. When it is necessary to replace the electrical device, it can be easily taken out by simply opening the two side levers, which are safe and easy to operate.

Furthermore, when disassembling with some tools such as screwdrivers, it is easy to touch other electrical devices, resulting in the risk of short circuits and open circuits of other control circuits. If it cannot be removed, only when there is enough space at one section or both ends of the DIN rail, the electrical devices can be removed in turn along the direction of the rail, which will bring extra workload to maintenance and repair personnel, and even reduce work efficiency. Unable to complete the set work within the effective time, resulting in the consequences of affecting industrial safety production.