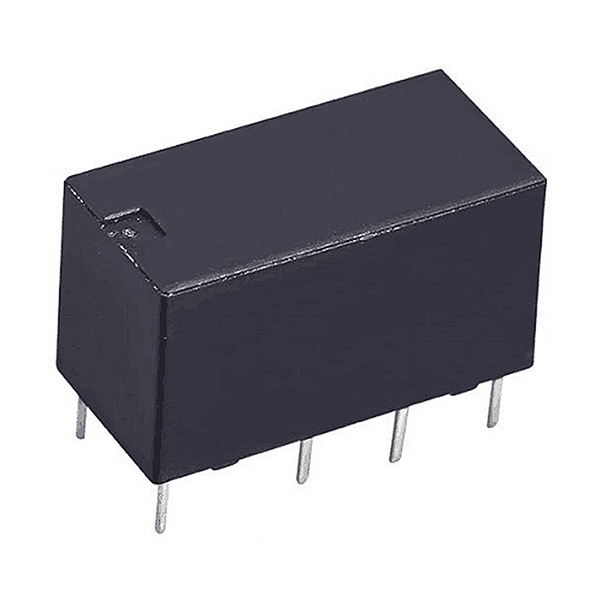

Signal Relays

Signal relay from Chinese manufacturer is a kind of common device in automatic control system, which are widely used for switch, anti-theft monitoring, communication equipment, office equipment, medical equipment and security alarm system. ATO manufactures 3V, 5V, 6V, 12V, 24V DC low signal relays at factory price, contact form DPDT/ SPDT available, small and compact. By designing and making its customization fully automatic production equipment to fulfill your needs, and hence to produce high efficiency and low power consumption protection relays.