Industrial SSR Solid State Relay

Single phase SSR-DA industrial solid state relay provided by ATO, features with 60, 80, 100, …, 350 Amp load current with 3-32VDC control 24-440V AC, high switching speed, no spark and no noise. It is a safe and reliable switching solution in the automation control fields such as petrochemical equipment, pharmaceutical machinery, food machinery, packaging machinery, plastic machinery, CNC machine tool and entertainment facilities, etc.

Specification

Model: ATO-GYSSR-DA

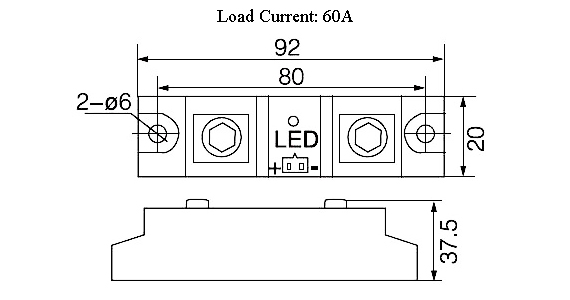

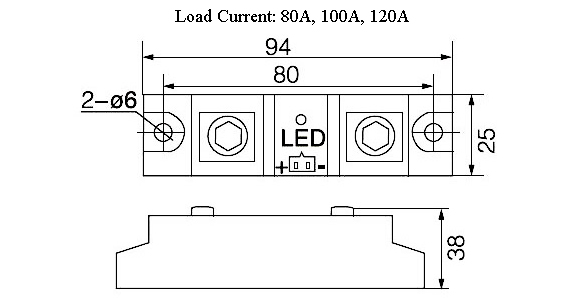

Load Current: 60A, 80A, 100A, 120A, 150A, 200A, 250A, 300A, 350A

Off-State Leakage Current: ≤4mA

Insulation Resistance: 1000MΩ/ 500V DC

Working Indicator: LED

Control Voltage: 3-32V DC

Load Voltage: 24-440V AC

Off-State Time: ≤10mS

Ambient Temperature: -20 ~ +70℃

Certification: CE, CCC, TUV, UL

Control Current: DC 7-32mA

On-State Voltage Drop: ≤1.5V

Dielectric Strength: 2500V AC

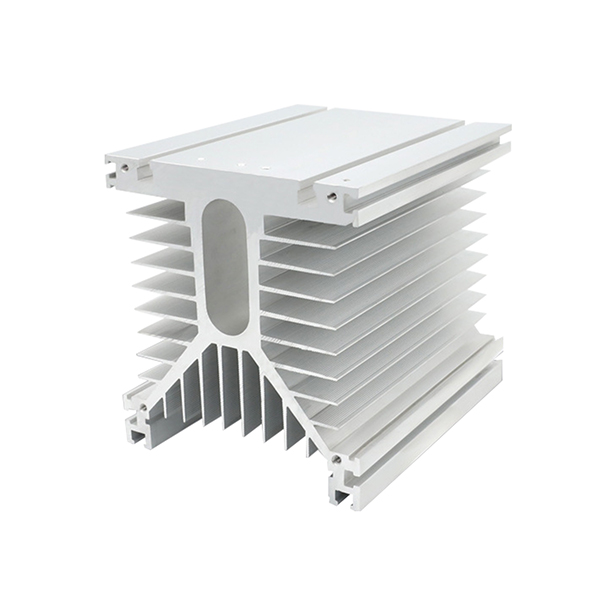

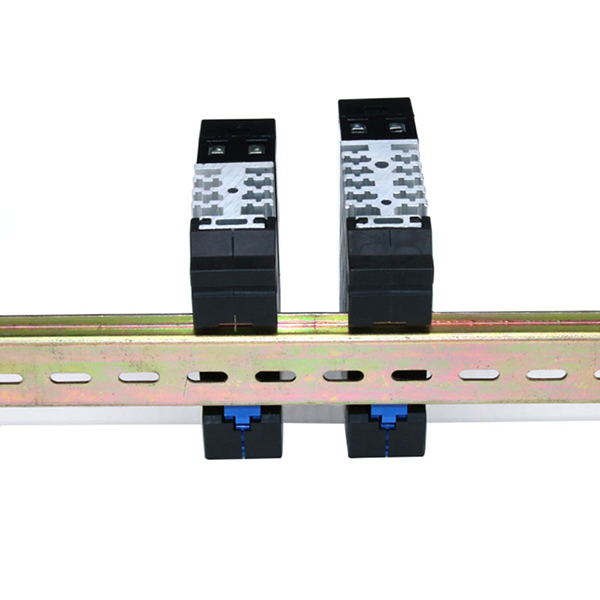

Mounting Method: Bolt Fixing

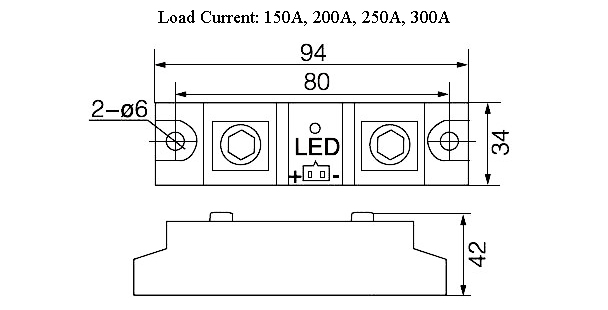

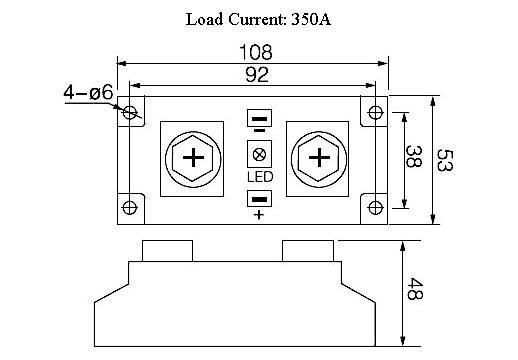

Dimension (Unit: mm)

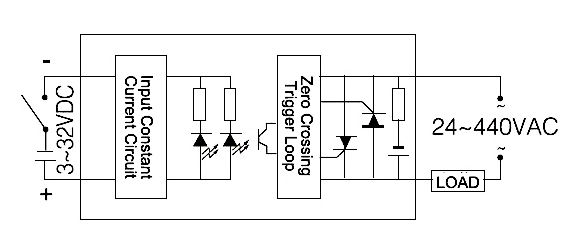

Wiring Diagram

Operation Note

- For the resistive load, it cannot exceed 60% of the rated current of the SSR.

- For the inductive or capacitive load, it cannot exceed 40% of the rated current of the SSR.

- For the electric motor, it cannot exceed 20% of the rated current of the SSR.

- Proper radiator or heat sink should be equipped for the industrial solid state relay. If the load cooling condition is not good, it is necessary to leave some margin. Avoid the load short circuit because over current and short circuit are the main causes for permanent damage of the internal SCR of the SSR.

- Over current protection: Using fast fuse and air switch is one of the methods for over current protection; fuse is also available for small capacity.

- Over voltage protection: It can adopt the parallel voltage-dependent resistor (MOV). The MOV area decides the absorption power, and its thickness decides the protective voltage value. Generally, 471/10D voltage-dependent resistor is suitable for 220V series SSR, 681/10D voltage-dependent resistor for 380V series SSR, and 821/10D voltage-dependent resistor for 480V series SSR.

Tips: What is an industrial solid state relay?

The input circuit of the industrial solid state relay provides a loop for the input control signal, making it a trigger signal source. Most of the input circuits of industrial solid state relays are DC input, some are AC input. The circuit of DC-AC solid state relay is divided into resistance input and constant current input. The input control current of a resistive input circuit is changing linearly with the input voltage. Constant current input circuit, when the input voltage reaches a certain value, the current no longer increases significantly with the increase of the voltage. This relay is suitable for a small range of input voltage.

The driving circuit of the industrial solid state relay may include an isolation coupling circuit, a functional circuit and a trigger circuit. At present, optocouplers and high-frequency transformers are widely used in isolated coupling circuits. Common optocouplers include phototriodes, optical triacs, photodiode arrays (photovoltaics), etc. The high-frequency transformer coupling is to form a self-excited oscillation of about 10MHz under a certain input voltage, and transmit the low-frequency signal to the secondary side of the transformer through the transformer core. Functional circuits can include detection and rectification, zero-crossing, acceleration, protection, display and other functional circuits. The function of the trigger circuit is to provide a trigger signal to the output device.